Buying and Repairing a Second Hand Wheel by Robert Linigen

The Venco cone drive wheel is like the Holden Kingswood of Australian Ceramics. Australian made, everyone has had one at some stage, and just about any one handy can keep them running. They are not the most powerful, or the quietest, but with a little love, they will probably last forever.

If you’re after a second hand wheel, due to their reliability, ease of repair and availability of parts, I’d really only look for a Venco. I've used wheels from Talisman from New Zealand , Shimpo from Japan and Brent from US. They make excellent wheels and you may be able to find parts online, but parts for some other long gone makes may be just unavailable.

I can’t think of another machine that will stand so much neglect and keep running for so long without complaint as a Venco wheel.

Like most colleges in Australia, the wheels at WSI, Nepean College are Venco. Ours were bought new in 1982 and are still going strong. A new Venco No 3 cost just over $1200 in 2014 and a Heavy Duty just over $1500. Venco don’t retail, but you can buy them new through any of the local pottery suppliers.

Second hand, they seem to go on eBay for $300-$600 or even less in a garage sale. A new one falls in price as soon as you get it dirty, and then keeps its price pretty much forever.

You might as well get the heavy duty model with the larger 13 inch wheel head ,if you can find one, because it has a larger ½ horsepower motor. The “No 5” model has a hand control and speed lock, which is useful. The models with 11 inch wheel heads used to get a smaller ¼ hp motor, but they are still powerful enough. Venco sell an optional seat, but an old office chair is fine and will adjust for your height.

The old compact models with the built in folding seat are similar mechanically, with a smaller ¼ hp motor, but the seat is too close to the wheel head to be comfortable unless you are shorter than me.

I believe Venco have sourced the motors from different places over the years, and some materials have been updated and the colours have changed. Pink when they began in the late 70’s, brown in the 80’s, then green for a long while. You can get them now in stainless steel or beige painted steel, but the basic design is unchanged for years.

You can see the current models at http://www.venco.com.au/wheels/std.htm

Venco Wheel Repairs

You control the speed of the wheel by the foot pedal, which moves the pivot and spring that holds the electric motor. At the end of the motor (under the motor and out of site in this photo) is a metal cone. The thin end of the cones turns the drive wheel and hence the wheel head slowly. Press the pedal down and the motor pivots and the wide end of the cone drives the ring and wheel head faster. Image by Rachael Cramer from Servant Ceramics.

If you buying a second wheel, give it a good look for stuff like rusty casing, frayed/ damaged power cords and perished plastic and rubber parts. Wheels offered for sale have may have been unused for years. Under a Venco wheel is ideal red back spider habitat, so be careful.

The oldest Vencos have a female electric plug that an extension cord plugs into. New extension cords have a plastic lip on the male plug end, so you need an old extension cord in good condition, rewire the end or modify the end of the extension cord by cutting away the plastic lip on a newer extension cord to power it.

So switch on the power. If it won’t start, there’s a problem with the cord or the motor or the power point. The motor very rarely wears out or shorts out. A new genuine 1/2HP motor is listed as $625 (2014). You can get the motor rewound for much less money, but you'll probably find another second hand wheel in better condition.

Does it speed adjust smoothly? The motor pivots through polyurethane grommets that perish after maybe 10-15 years These can be replaced pretty simply, and just tightening loose motor mounting bolts or perished fibre washers may fix excess vibration.

Getting the hard polyurethane grommets in can be a struggle. I heat them in hot water to soften them up and use a lubricant. Oil based grease will shorten the life of polyurethane. You can get a special polyurethane lubricant like Poly Ease or just use a water based "personal lubricant" and carefully lever them in using a blunt screwdriver like a tyre lever on a bicycle tyre.

Paul Gould shows how to replace the grommets in this video

Pie Bolton developed this special tool to replace the grommets on Venco wheels. "The tool is easy to make from bits and pieces from any hardware store or maybe lying round the studio - The chrome piece is just a cut down section of chrome towel rail and serves to guide the grommet through the hole in the body of the Venco. Just set the bits up in this order, feed it through the hole, tighten the nut and the grommet will push through the hole. You can heat it to make it easier if you like. This tool saved me a lot of heartache!"

Does the wheel speed slow and stop when you take your foot off the wheel? If the motor isn't disengaging, then check the 2 springs. They lose tension eventually and butare easily replaced. You can shorten the spring as a short term quick fix.

Get the wheel moving at speed and push down firmly with a damp sponge on the wheel head. Does the wheel slow down easily? If so, the rubber drive ring is worn or perished. Feel for worn or perished rubber. The drive ring will need to be replaced now and then.

If there is a knock, as the wheel turns, like a scratch on a vinyl record (ask your parents) the ring may have a notch, where someone has stomped down on the pedal with the wheel stopped. Common in ex school wheels and the drive ring will need to be replaced.

Replace the ring by taking off the large spring and moving the motor and cone out of the way. Then undo the single lock bolt and you can usually wrestle the drive ring off with some effort. It is a tight fit and it's easier to use a gear puller tool if you have one.

The bearings? Is there any sideways movement in the wheel head? Up and down is OK, but not sideways. Does the wheel head turn smoothly and quietly with the motor off and disengaged? The Venco bearing is pretty well sealed, but leaving the tray full or water or slurry can let clay in and grind away at the bearings. If it is badly worn or seized, it can be replaced. although I've never had to replace one myself.

As guide to spare part prices in 2014, grommets are around $3 each, new drive rings are now just over $100 and a bearing kits are around $60. You may be able to get non genuine parts fractionally cheaper but I haven't really tried except for nuts bolts and washers. Any of the Venco agents will order and post spares to you and can probably recommend someone to give an estimate and do the repairs if you don't want to do it yourself.

That’s pretty much all that can go wrong. Get a wheel and practice!

(Disclaimer: This is all my own humble opinion. I don’t have any tie to Venco at all. The Venco stuff I’ve bought has been second hand or retail through local pottery suppliers.)

But nothing lasts forever. RIP my old Venco lost in the bush fires, 1978 -2013.

Kickwheels

Kickwheels A well designed and built kick wheel can be beautiful thing. Quiet, no need for electricity, great low speed control that can help get a looser feel to your pots. Better for small pots up to a 2-3 kg. Make sure the flywheel is heavy enough for you to centre easily. Many are homemade and their quality depends on the skill of the maker and the plan. The Nepean TAFE library has copies of a good plan for a kickwheel by Leonard Smith. Check it out if you are interested in building one. The Leach kickwheel is a another classic, timeless design. Check out this youtube video of Simon Leach discussing the wheel designed by his grandfather, Bernard Leach.

Kirk Winter throwing on his Korean style Oonga wheel, that he built from hardwood, concrete and a Toyota Hilux axle.

Throwing Standing Up

Production throwing for many years puts a lot of strain on your back. I now throw standing up. The right height for me seems to be about halfway between the belt and the belly button.

You can get a “stand up kit “ for a cone Venco wheel, but the height is not adjustable and would only suit someone a fair bit shorter than me at 179 cm. You could simply put the whole wheel on blocks or a low bench, but then you have the foot pedal too high and balance on one leg, or you must use a hand lever to control the speed.

The number 5 model comes with a hand lever that looks like a gear stick and locks into one of 5 holes in a bracket pop riveted to the casing. You then control the wheel by using the hand control locking in 1 of the 5 speeds. You could probably improvise a hand control if you have another model. You then just need to put the wheel on a bench that is the right height for you.

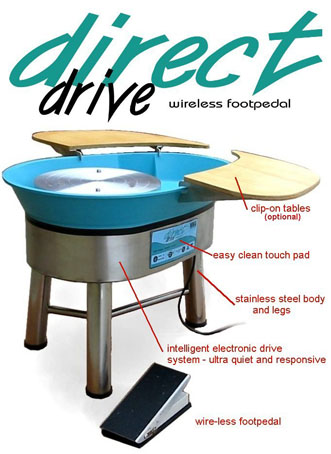

But I bought an Australian made Venco direct drive wheel. There is no ring or cone, just an electric motor and electronic control. The foot pedal is a battery operated radio transmitter wirelessly controls wheel speed. The 2 C batteries last 1-2 years for me and I have no idea how long the electronics should last. The cable is held onto the casing with a plastic bracket, which fell off after a year. I glued the bracket back on and everything else is good.

The wheel is quieter and smoother than a cone drive Venco and has more than enough power to centre tableware pieces easily.

We have one of these wheels at Nepean TAFE and I had another in my Yellow Rock studio. They're used without their legs on a bench. The height is adjusted for taller throwers by stacking wooden blocks underneath. I adjust the height of mine depending on the work. Lower to get more downward pressure for my big platters and a few cm higher for taller vessels or trimming bases. I like the more active posture of throwing standing, can more easily stand back to see the form or grab a tool. Holding a fixed posture for too long was giving me some back pain.

Potter’s Wheels and Potter’s Back

Wheel forming or throwing can be hard on your back. It is important to keep a good posture to avoid back problems.

You are aiming to keep your back straight, and pivot from your hips rather than slouching down. This means you are using the front of the seat only, and you don’t need a seat with a back or arm rests.

Venco makes a seat that’s a simple metal rod frame bench, with a chipboard seat covered in foam and vinyl. Simple and durable, but not height adjustable for taller or shorter people.

At NepeanCollege, we use plastic office style chairs that came without the back. Easy to clean, and adjustable, although some of the adjustment levers have now broken off.

Some potters prefer a seat that is tilted down toward the wheel head, to encourage good posture. Some office chairs will tilt forward quite a bit, like Emily Murphy’s seat, described in her blog

http://potteryblog.com/2007/10/simple-tweaks-to-a-better-wheel-set-up/

and some potters take a simple wooden chair and modify it like John Zentner

http://jzpottery.blogspot.com/2007/09/adjustments.html

or Robert Compton's wheel page

The Venco sit down cone drive wheel only turns when the pedal is pressed down, it doesn’t lock in like some other brands. This means your hips are not level, with your right leg up on the pedal and your left leg on the floor, and this can hurt your back. Try the low tech method of using a house brick under your left heel to keep your hips level.

After years of full time production throwing, and some back problems, I found it hard to break bad habits and now prefer to throw standing up.

Other potters have had similar problems and made adjustments. Link to John Glick article http://www.studiopotter.org/articles/art0008.htm

To avoid back problems, try to maintain good general fitness, stretch before and after a throwing session , keep good posture at the wheel and don’t hold a position for too long without a break. This means standing up and stretching every hour or so, not a cigarette and coffee after every pot. It takes time and concentrated practice to develop skill at the wheel. As your skill level increases you will find you are using less physical effort to throw each pot and you should be able to avoid any health problems.

Traditional Indian potter's wheel, used by Bhuvnesh Prasad at the Stepping Up ceramic Conference.

Other Wheels

Here's some other wheels that have been sent to me or I've come across on the internet. I've never used them, but they look like fun. Maybe not the best wheels to learn on.

Hillar Bergman builds a potters wheel from a car wheel and plumbing fittings.

Hilar Bergman throws on his car tyre wheel

You can even mount a potters wheel on the towbar of your car

using a car as a potters wheel This guy uses a car wheel as a potter's wheel while it's still attached to the car. Remember to chock the wheels first!

Or maybe make a potters wheel from a mop bucket

Or check the spoof Captain Ceramics X1 Potters wheel, powered by a 300 hp Oldsmobile engine.

Alternate power source for pottery wheels? Maybe you can use potter David Pier's HoundRound